Penetrating Agents

Introducing our advanced Penetrating Agents, a crucial ingredient to enhance efficiency and effectiveness of your textile processing operations .Our Penetrating Agents is the ultimate solution for you whether you are in the textile manufacturing industry or involved in specialized fabric treatments, with outstanding performance and reliability.

This is Fiber Penetrating Agents, which our company has particularly tailored. It ensures effective absorption and distribution of dyes, chemicals, and finishes by penetrating deeply into fibers in a uniform manner. Such an attribute results into a more vibrant color and consistency throughout the final product, thus making it an essential ingredient for quality fabric finishing.

It works as a Textile Penetrating Agents that stands out in different stages of textile processing including pre-treatment, dyeing and finishing. That way; fiber wettability is improved leading to faster saturation during wet treatment processes. This Quick Penetrating Agents feature will significantly cut down processing time while improving productivity hence making your business more efficient.

Our Penetrating Agents for Textile Applications can be used on various materials such as cotton and wool among natural fibers as well as synthetic types like polyester or nylon. In modern day textile manufacturing, this flexibility makes it indispensable since it addresses different kinds of fabrics and treatment needs.

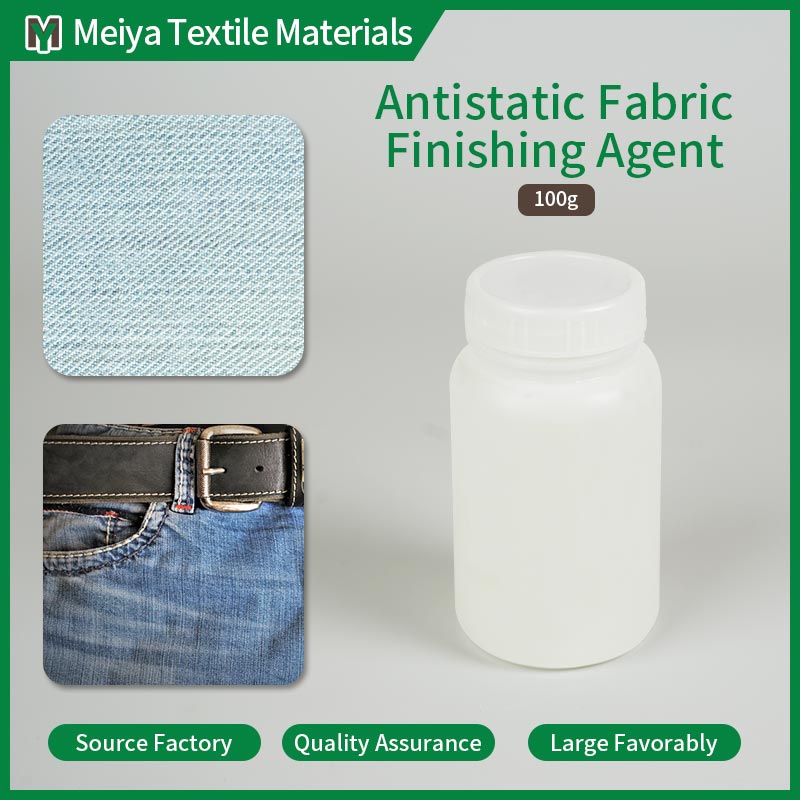

In addition to its ability to penetrate fabrics, our product also acts as a Textile Antistatic Agent. During textile processing or even at the end product stage it helps prevent static build-up ensuring that the textiles remain soft and manageable. The Antistatic Agent for Textile characteristic is especially useful within dry environments where the presence of static electricity can create substantial problems,

To achieve our product’s aim our Penetrating Agents was formulated with safety and environmental concerns taken into consideration too. It does not contain any harmful substances hence non-toxicity factor sets it apart from other similar products within sustainable textile production contexts because this meets all industrial norms pertaining to green cloth making industries. This means that better performance can be achieved without any harm being done to the environment and human health.

Application of our Penetrating Agents is simple and user-friendly. Batch or continuous processing systems can easily integrate it. As a result, you can always trust on this item during your quest for uniformity in myriads of fabric finishes.

For those looking forward to increasing their textile processing efficiency, we have our Penetrating Agents. It not only improves penetration of processing liquids into fibers but also enhances overall quality of fabrics and efficiency in the entire process. Therefore, this is an essential part of any textile processing setup regardless of whether it is meant for mass manufacturing operations or specialized fabric treatment practices.

In summary, our Penetrating Agents has dual functionality as both Fiber Penetrating Agents and Textile Antistatic Agent making it outstanding in textile processing .With Quick Penetrating Agents, it takes the shortest time possible to soak into fibre while the inclusion of different types of cloth makes it a versatile option for diverse textile uses. Incorporate our Penetrating Agents into your textile processing program to improve efficiency, achieve high-quality fabric and sustainable production processes thereby enhancing environmental friendliness. Choose our Penetrating Agents for Textile as well as get advanced reliable eco-friendly means of dealing with textiles during the production process.

Get MEIYA Penetrating Agents to Delight Your Customers

Check out our line of Penetrating Agents, which have been tailored to aid in the textile production through enhanced fiber infiltration and antistatic nature. Good for different types of materials, our Penetrating Agents ensures effective coloration, quick wetting, and lasting effects.

Our company is the one-stop shop for the best quality Penetrating Agents that has been used by people worldwide for many years due to its chemical solutions for textiles. At this firm we are always guided by innovation and sustainability to assure that our Penetrating Agents meet the highest standards in the industry.

How does a Penetrating Agents work?

Penetrating Agents work by reducing surface tension and enhancing the wettability of fibers. This allows dyes and chemicals to penetrate deeply and evenly, leading to more efficient and uniform processing.

Is a Penetrating Agents safe for all fabrics?

Yes, Penetrating Agents are generally safe for a wide range of fabrics, including natural fibers like cotton and wool, as well as synthetic fibers such as polyester and nylon. Always check the product guidelines for specific fabric compatibility.

Can Penetrating Agents be used in all stages of textile processing?

Penetrating Agents can be used in various stages of textile processing, including pre-treatment, dyeing, and finishing. They enhance the overall effectiveness of each stage by improving the penetration and absorption of processing liquids.

What are the benefits of using a textile Penetrating Agents?

Benefits include improved dye and chemical penetration, enhanced color consistency, reduced processing times, and better overall fabric quality. Additionally, they can contribute to more efficient and sustainable textile manufacturing processes.

How do you apply a Penetrating Agents in textile processing?

Penetrating Agents are typically added to the processing bath or applied directly to the fabric. They integrate easily into existing processing systems, whether for batch processing or continuous operations, ensuring consistent and effective results.

Are Penetrating Agents eco-friendly?

Many modern Penetrating Agents are formulated to be eco-friendly, being non-toxic and biodegradable. They comply with industry standards for sustainable textile processing, ensuring minimal environmental impact.

What is a fiber Penetrating Agents?

A fiber Penetrating Agents is specifically designed to penetrate deeply into textile fibers, ensuring thorough and uniform absorption of dyes, chemicals, and finishes. This leads to superior fabric quality and consistency.

Can Penetrating Agents reduce static in textiles?

Yes, some Penetrating Agents also function as antistatic agents, helping to reduce static buildup during processing and in the final product. This makes fabrics easier to handle and more comfortable to wear.

What is a quick Penetrating Agents?

A quick Penetrating Agents is formulated to enhance the speed of liquid absorption into fibers. This reduces processing times and increases efficiency, making it ideal for high-speed textile manufacturing environments.

Do Penetrating Agents affect fabric feel?

Properly used, Penetrating Agents do not negatively affect the feel of the fabric. In fact, they can improve the fabric's texture by ensuring uniform treatment and preventing uneven dye or chemical application.

Are there specific Penetrating Agents for different types of textiles?

Yes, there are specialized Penetrating Agents designed for different types of textiles, including natural and synthetic fibers. These agents are formulated to meet the specific needs of each fabric type.

How long does it take for a Penetrating Agents to work?

The time required for a Penetrating Agents to work depends on the specific product and application method. Generally, they work quickly to enhance fiber absorption, often within the same processing cycle.

What role does a Penetrating Agents play in dyeing?

In dyeing, a Penetrating Agents ensures that dyes penetrate deeply and evenly into fibers, resulting in vibrant, consistent colors and reducing the likelihood of uneven or patchy dyeing.

Can Penetrating Agents be used with other textile chemicals?

Yes, Penetrating Agents are compatible with a wide range of other textile chemicals, including dyes, softeners, and finishes. They can be used in conjunction with these products to enhance overall processing efficiency and fabric quality.