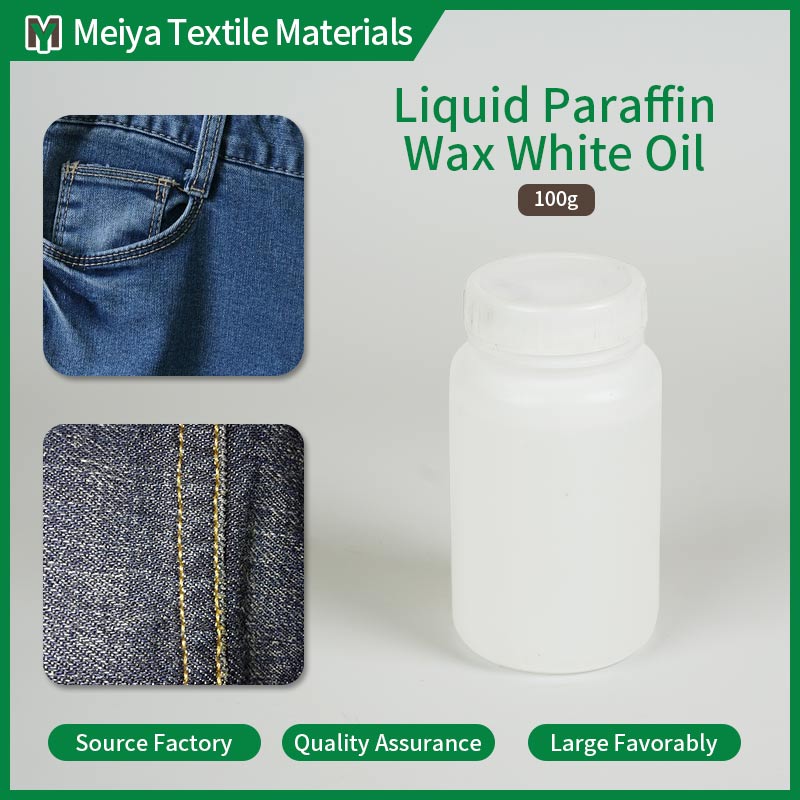

Light Liquid White Oil

Please click the button below to contact us.

Introduction:White Oil, a vital substance in the textile industry, serves diverse purposes. Its colorless and odorless properties make it ideal for fabric softeners, enhancing the feel of textiles. Additionally, light liquid white oil is used as a lubricant in textile machinery, ensuring smooth operations.

Product Description

white oil, a vital substance in the textile industry, serves diverse purposes. Its colorless and odorless properties make it ideal for fabric softeners, enhancing the feel of textiles. Additionally, Light Liquid White Oil is used as a lubricant in textile machinery, ensuring smooth operations. The water-resistant nature of White Oil contributes to protective finishes for textiles, improving durability. Its versatility and compatibility with various fabrics make light liquid paraffin widely used in different textile processes, enhancing the overall quality of textile products.As a known Light Liquid White Oil supplier, we supply the best products available within the industry to ensure smooth operations. By using our white oil, manufactured by us and supplied to textile makers, you are able to realize considerable gains in productivity without putting into jeopardy the quality of their products.

White Oil Features:

The fabric softening, lubricating, water-resistant features, colorless and odorless nature, compatibility, stability, versatility, non-reactive characteristics, and cost-effectiveness of White Oil make it a valuable and preferred choice in the textile industry, addressing various manufacturing needs and enhancing the quality of textile products.

1. Fabric Softening:

Enhanced Texture: White Oil acts as an effective fabric softener, improving the overall texture and feel of textiles for increased comfort and appeal.

2. Lubricating Properties:

Smooth Machinery Operations: Used as a lubricant in textile machinery, ensuring frictionless and efficient operations, leading to extended machinery lifespan.

3. Water-Resistant Finishes:

Improved Durability: Contributes to water-resistant finishes for textiles, enhancing their durability and making them suitable for a variety of applications.

4. Colorless and Odorless:

Preservation of Fabric Characteristics: White Oil's colorless and odorless nature ensures that it does not alter the visual or olfactory aspects of textile products, preserving their natural characteristics.

5. Compatibility with Fabrics:

Versatile Application: Exhibits compatibility with a wide range of textile materials, making it versatile for use in different fabric types and manufacturing processes.

6. Stability in Formulations:

Consistent Product Quality: Provides stability to textile formulations, contributing to the consistent quality of end products over time.

7. Versatility in Applications:

Flexible Usage: White Oil's versatility allows for its application in various textile processes, from fabric softening to lubrication and protective finishes.

8. Non-reactive Characteristics:

Chemically Stable: Possesses non-reactive properties, ensuring that it does not negatively interact with other components in textile formulations, maintaining stability.

9. Cost-Effective Solution:

Economic Efficiency: Offers a cost-effective solution in textile processes, contributing to efficient manufacturing practices without significantly increasing production costs.

White Oil Application:

Spinning and Weaving

White Oil is important during the spinning and weaving phases of textiles manufacture. Its moderate friction aids in the reduction of friction between fibers and machinery components. It extends the service life of machinery as well as the life of textile materials, which in turn increases productivity in terms of time and production resources.

Maintenance of Textile Machinery

Light Liquid White Oil finds its application as a lubricant for textile machines and consistent operation of the machines is made a possibility. Economical maintenance costs for manufacturers of textile machines is achievable because our White Oil inhibits rust and corrosion build-up, thus increasing equipment life expectancy.

Fabric Finishing

White Oil is applied during fabric finishing in order to assist in the softening and smoothing of the textiles. It improves the surface of the fabrics and gives them added protection so they are more comfortable and last longer.

Dyeing and Printing

In the phases of dyeing and printing, the blockages are avoided and smooth ink flow is maintained by the addition of White Oil. Since there are no impurities in its composition, there will be no contaminants compromising the quality of dyes or inks, thereby keeping the color and pattern uniform on all textile products. This enhances the quality of the end products and lowers chances of production defects.

Textile Coatings

White Oil is often used in one or other phase of a process where textile coatings are applied in order to achieve a silky appearance and avoid fraying or other damage to the fibers. It is useful in the making of coated materials with high performance capabilities towards abrasion, tearing and even adverse environmental conditions.

White Oil FAQs:

1. What are the benefits of White Oil in the textile manufacturing processes?

The efficiency of the textile manufacturing processes is greatly enhanced with the use of White Oil. White Oil, when employed in spinning, weaving, and finishing, is a suitable lubricant that minimizes surface friction between elements of machinery and fibers. Our White Oil extends the life and enhances the quality of the textile products allowing textile producers’ production rates to be high and interruptions to be minimal.

2. Can your White Oil be used with all kinds of textile machines?

Yes, our White Oil is multipurpose, and can be applied in different types of textile machines. Whether it is a high-speed spinning machine, a weaving loom, or tacks and finishing equipment, our Light Liquid White Oil gives the most effective lubrication and protection. It reduces the friction, enhances corrosion resistance, and increases the durability of the vital wear and strain components.

3. How can I be sure of the quality and purity of your White Oil?

We are a dependable White Oil producer and supplier. The White Oil we sell is subjected to extensive research and has the required industry measures. It goes through the best processes to ensure that it is of high purity and low aromatic content while being stable. We examine every batch for uniformity and upon clients’ request, we issue certificates of analysis as a proof of the acceptable quality of our products.

4. What are the appropriate storage conditions for White Oil?

Proper storage techniques are quite essential in guaranteeing the desired quality components of White Oil. The product must be kept in a cool and dry environment shielded from sunlight, heat and open flames. The practice of keeping the oil in tightly sealed containers is advised to avoid the presence of contaminants and moisture.

5. What precautions should be taken when using White Oil?

Our White Oil is one of the finest refined White Oil available but this White Oil contains a number of minerals so it cannot be used without care. Protective gloves and goggles should be used in order to prevent any skin or eye exposure. Large use of this oil should be conducted in well-ventilated areas to avoid overexposure to it.