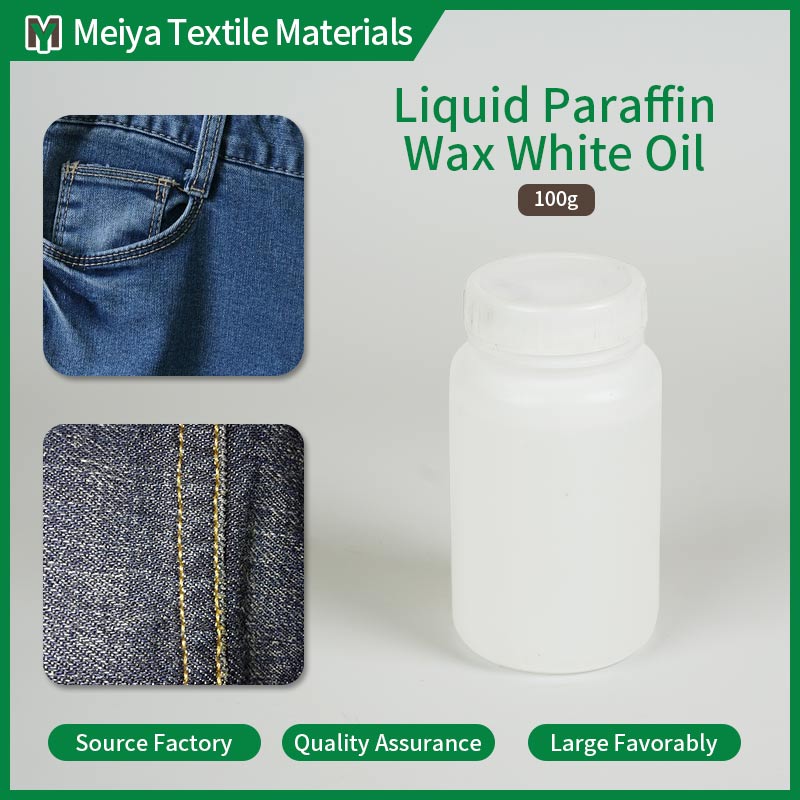

Liquid Paraffin Wax White Oil

Please click the button below to contact us.

Introduction:Liquid Paraffin Wax, commonly known as White Oil, plays a crucial role in the textile industry. Its colorless and odorless properties make it ideal for applications in fabric softeners, enhancing the texture and feel of textiles. Additionally, Paraffin Oil is used as a lubricant in textile machinery, ensuring smooth operations and reducing friction.

Product Description

liquid paraffin wax, commonly known as White Oil, plays a crucial role in the textile industry. Its colorless and odorless properties make it ideal for applications in fabric softeners, enhancing the texture and feel of textiles. Additionally, Paraffin Oil is used as a lubricant in textile machinery, ensuring smooth operations and reducing friction. The water-resistant nature of Liquid Paraffin Wax makes it valuable in creating protective finishes for textiles, improving their durability and performance. Its versatility and compatibility with various fabrics contribute to its widespread use in different textile processes.

Liquid Paraffin Wax Features:

The fabric softening, lubricating, water-resistant, colorless and odorless nature, compatibility, stability, versatility, non-reactive characteristics, and cost-effectiveness of Liquid Paraffin Wax (White Oil) make it a valuable and preferred choice in the textile industry, addressing various manufacturing needs and enhancing the quality of textile products. Liquid Paraffin Wax, or White Oil, offers several distinctive features and advantages when applied in the textile industry:

Fabric Softening

Acts as an effective fabric softener, enhancing the texture and feel of textiles for improved comfort and appeal.

Lubricating Properties

Functions as a lubricant in textile machinery, ensuring smooth operations and reducing friction during manufacturing processes.

Water-Resistant Finishes

Valuable in creating water-resistant finishes for textiles, contributing to increased durability and performance, especially in products that require protection against moisture.

Colorless and Odorless

Maintains the natural appearance and characteristics of fabrics due to its colorless and odorless nature, ensuring that it does not impact the visual or olfactory aspects of textile products.

Compatibility with Fabrics

Exhibits compatibility with a wide range of textile materials, making it versatile for use in different fabric types and manufacturing processes.

Stability in Formulations

Provides stability to textile formulations, contributing to consistent product quality and performance over time.

Versatility in Applications

Versatile in various textile applications, including softening agents, lubricants, and protective finishes, offering textile manufacturers flexibility in achieving specific product characteristics.

Non-reactive Characteristics

Possesses non-reactive properties, ensuring that it does not adversely interact with other components in textile formulations, contributing to the stability of the overall product.

Cost-Effectiveness

Offers a cost-effective solution in textile processes, contributing to efficient manufacturing practices without significantly increasing production costs.

Where can we use Liquid Paraffin Wax?

Waterproofing Treatments

Liquid paraffin wax is also a waterproofing agent applied to denim fabrics. With the application of water-repellent wax, denim fabrics are now ready to penetrate the outside environment. In this way, consumers are happy that there’s both pleasure and functionality in what they wear.

Finishing and Softening

For the finishing step, the textile liquid paraffin wax works as a softener. Use of this wax also brings a smoother touch which creates a better comfort feeling while wearing denim. It’s an application that has great advantages to various kinds of premium denim industries that focus on their customers’ comfort and feeling of the product.

Color Retention

The use of Liquid paraffin wax helps them achieve a more saturated look when maintaining the saturation of older colored denim fabrics. This adds an additional protection layer thus preventing excessive fading of denim colors during washes or wear and tear. This application is significant for the brands which want their denim products to always portray the same look.

Anti-Creasing Properties

Liquid paraffin wax can also be used to solve problems of creasing and wrinkling in denim. It enables the finished garments to always retain new looks especially when displayed on retail racks. Brands find this application to be advantageous as it offers consumers easy care type of garments.

Improved Strength and Flexural Endurance

Adding Liquid Paraffin Wax while producing denim makes the material more robust. It acts as a shield against weakening and fraying of fabric, thus prolonging the life of denim goods. The manufacturers have the assurance that their denim will be considered to be of exceptional quality and reasonably long-lasting, meeting the needs of budget-conscious buyers.

Liquid Paraffin Wax FAQs:

1. What are the primary benefits of using Liquid Paraffin Wax in denim manufacturing?

Several benefits can be obtained using Liquid Paraffin Wax in denim making processes including, but not limited to, water repellence, increased strength and softness. Additionally, it helps to keep the colors bright and minimize wrinkles, which helps to increase the quality level of the item produced.

2. Is it safe to use Liquid Paraffin Wax in denim products?

Our Liquid Paraffin Wax is appropriate for use in denim products. It is produced with the required standards and regulations, thereby making it compliant with safety standards for textiles and is free from hazardous materials.

3. In what way Liquid Paraffin Wax improves the dyeing process of denim in particular?

By employing Liquid Paraffin Wax the los of color during the washes can be minimized providing stronger dyes which are further embedding clotts to the angles, practically designed to keep the original colors deep and pleasing.

4. What is the recommended application method for Liquid Paraffin Wax in denim?

Liquid Paraffin Wax can be applied at various stages depending on the effect it needs to achieve. It is possible to apply at the finishing stage through either padding or spraying. We encourage you to perform such experiments in order to find what is suitable in your particular production cycle.

5. Can we combine any paraffin wax’s application with other treatments?

Yes, it is possible, for example Liquid Paraffin Wax can be used with softeners and waterproofing agents. This flexibility of usage enables denim manufacturers to enhance the performance characteristics of the produced products. However, it is prudent to conduct the tests for combinations so as to ascertain compatibility and obtain intended results.